Free Stall Hall

(Performed by Intel Farm Company)

* Design and construction of the largest and most equipped hall free stall in the country with a capacity of 1000 cows

* Height of the floor to the crown of the shed: 13 meters

* Use only 4 columns with very small dimensions

Parts of Free Stall Hall

ceiling

It is covered with two layers of fiberglass insulation for proper air circulation.

* Drinking:

With granite and cold resistant, shock and keep the water cool in hot seasons and its extremely low price compared to the same product made of steel.

* Hall floor:

Creating a suitable bed with roughness compatible with the natural environment of livestock and very resistant with the help of carpet bricks

*Metal:

Made of ST37 steel with 52 meters opening and 180 meters hall length.

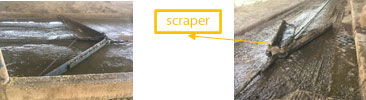

* Fertilizer collection system:

One of the most important goals in the management of industrial livestock manure is the optimal collection of waste with maximum efficiency in the shortest possible time. These scrapers are able to collect waste in the hallways of free stalls or even springs.

* Use of air fan and spray:

To provide the required humidity and reduce the temperature and relieve heat stress of livestock that

Increases the fertility of the dairy herd during the summer season, air fans and sprayers are installed in the free stall hall.

Features of Free Stall made by Intel Farm Company

-Use standard hot-dip galvanized pipes with suitable weight

-Use dry bolts

-Bending using a hydraulic system without the slightest shrinkage

-High production speed

-Use of CO2 welding to increase the strength of the free stall frame

-Ability to change the size in a sliding way to keep livestock with different sizes

-Ability to open all parts as bolts and the ability to move the frame

Livestock feed factory

The feed factory has the following sections:

1- Raw material receiving system

2. Mill system

3. Partitioning and mixing system

4. Pelting system

5. Packaging system

In general, the same method is used in all feed mills and only the final product is somewhat different.

Corn storage silos

Silo is a warehouse for storing food used in human and animal nutrition. Silo in animal husbandry is usually a place where high humidity forage is stored so that it can be used for many years without changing the nutritional value of the forage much.

Corn Storage Silos

(Performed by Intel Farm Company)

The largest silos in Middle East at present with a nominal capacity of 70,000 tons are in Company. Which is transferred to the ground by wall-to-ground method with value analysis and engineering due to cost reduction and is different from moat method. Drainage from the sides to the middle ramp of the silos is done by septic method and by means of pumping.

Hay Depot

The hay warehouse building has a drainage system, shorter walls to prevent water from entering and a fire extinguishing system.

Launching 12,000 dairy farms-Performed

- Super User

- Livestock projects

- Hits: 162