Features of accumulation pools of liquid compost of Heevco Holding

Agricultural lands engaged so far: Over 9 hectares

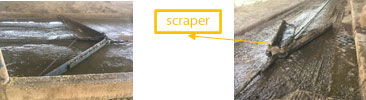

Environmental problems caused by compost earthen pools:

At present, liquid compost backwater exited from Heevco Holding is conducted towards fields down the company using some canals and cumulated in totally earthen pools. It takes a long time after evaporation of its liquids (about 4 years) to change into dry compost and become usable. This present system has made plenty of technical, financial and environmental problems:

1- In these pools, cumulated liquid composts whose solids always cover water's surface, it demands a long time for the water existed down these composts to evaporate so that their solids could be separated. Consequently, this engages the fields for a long time and provides a lot of time for polluted waters to leak into down surfaces and underground waters and lead to their pollution.

2- With regard to technical system and the existing pools' being marshy, it is not possible for the workforce and the equipment to work and separate compost from water which it caused several compost pools to be made and most part of the farms to become polluted and unusable

3-From among other problems of these pools, it can be mentioned that when heavy seasonal raining, the pools' output rate of flow becomes uncontrollable that it makes downstream fields get polluted that it, in turn, results in various environmental problems and the contest of the owners of the said fields.

4-Furthermore, the lands from which they use as earthen pools of compost accumulation, cannot be cultivated in no way even many years after movement and depletion of compost.

Statement of the problem:

In recent decades, because of increasing population and changing classic dairy farms into modern and enormous ones, it is needed to take new measurements to manage compost so that they could keep the system economically strong; and it can supply the current needs of world community. Nowadays, husbandries and especially dairy farms require to be managed effectively in terms of environmental, economical and energy-based subjects. From 1960s, extraction of liquid compost from husbandries has found many proponents, so the process of separating liquid –solid plays an important role in management of manures but knowing the limitations and the fields of their function are also essential.

The advantages of separating manures are the following: improvement of transportation conditions, decreasing danger of water and soil resource pollution, decreasing bothering factors such as stink, meeting health affairs and enjoying value added of products of solid and liquid composts.

Using the equipment separating compost from water, a way to save the time and not to need lots of earthen pools :

In most of the advanced countries, you can see these equipment for instance, in Ontario, Canada, a machine has been built that can enter the compost gathering pools and move solid compost, having several nuzzles; and gather them in one side. This machine has the capacity of moving 12000 gallons of liquid compost (around 45000 liters) per minute. It is an amphibian vehicle that has been designed for arousing lagoons. Having some suckers, it pumps the liquid part of composts and injects them into the lands. After it was made in 2014, demands for Lagoon Crawlers raised; and now, over 175000 machines are working in modern dairy farm.

Building Geo membrane pools; a solution to eliminate earthen pools:

In this respect, for collecting liquid compost, it is better to determine one pool instead of using a large number of pools and create proper substructures like using geo membrane pools on the pools' floors as they have capability of entering the equipment like logons. Cumulated liquid compost whose solids always cover water's surface, demanding a long time for the water existed down these composts to evaporate so that their solids could be separated by this equipment. In such a way, building geo membrane pools that, in no way, do not let liquid compost penetrate into down surfaces of soil causes the liquids not to need a long time to evaporate and change into a dry and extractable compost. As a result, the environment, underground waters and agricultural parts are not damaged.